Supporting Offshore Wind Power with Technological and Human Resources.How the Pioneer in Wind Turbine Maintenance, Hokutaku, Is Shaping a Uniquely Japanese Supply Chain

Offshore Wind Power—The Trump Card in Renewable Energy

Stretching out in a wide expanse of ocean, wind turbines stand tall. Their blades slowly turn in the steady sea breeze.

Offshore wind power, as the name suggests, entails installing wind turbines out at sea, harnessing maritime winds to drive the turbines and generate electricity.

In recent years, the turbines themselves have grown in scale. Some now reach roughly the height of Tokyo Tower (about 300 m) from the sea surface to the blade tip. The key advantage of operating offshore, rather than on land, is the absence of large obstructions, enabling strong, stable winds.

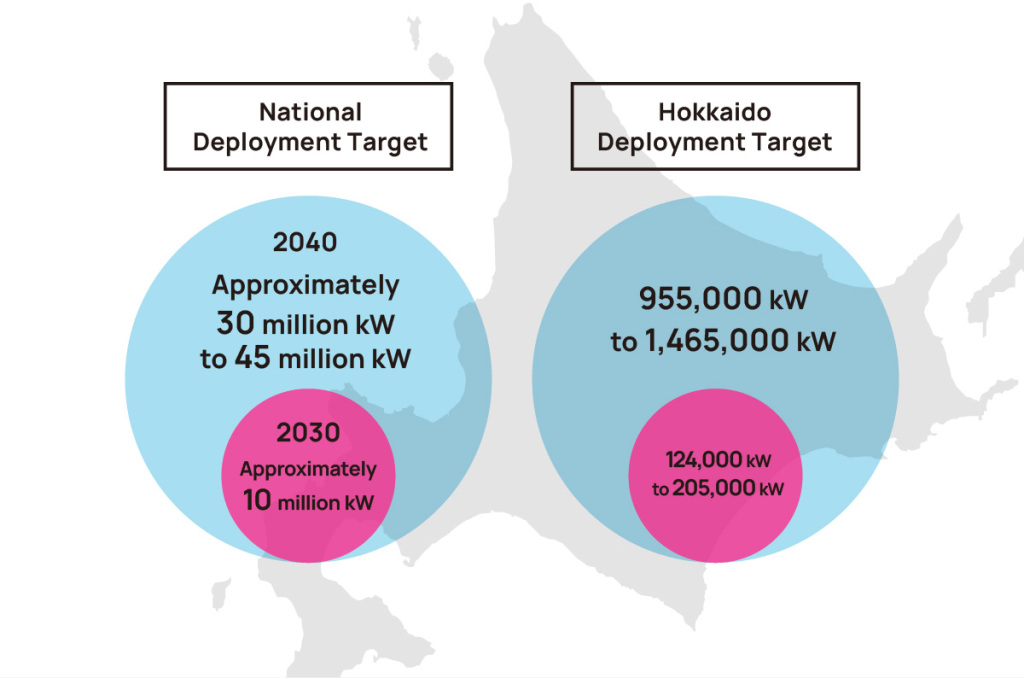

Surrounded by ocean on all sides, Japan holds high potential for offshore wind power. As of the end of December 2023, 39 turbines are in operation nationwide, with a total output of 153.5 MW. The government views offshore wind power as a pivotal source of renewable energy and aims to bring 30–45 GW online by 2040—two hundred times the current capacity.

Source: Created based on “Offshore Wind Power Initiatives in Hokkaido” by the Hokkaido Zero Carbon Promotion Bureau, Department of Economic Affairs.

Europe is considered a global leader in offshore wind. In 2023, installations there totaled 34.1 GW, more than two hundred times Japan’s figure. Underlying factors include:

- Countries like the UK, being island nations with long coastlines, enjoy relatively shallow coastal waters conducive to turbine installation.

- Surrounded by the North Sea and the Atlantic Ocean, these areas benefit from stable westerly winds.

Wind turbines, at their core, consist of the rotor portion and what is known as “BOP” (Balance of Plant)—in other words, foundations, subsea cables, and other non-turbine components. One of the most critical considerations is the installation method.

Europe predominantly uses “fixed-bottom” foundations, anchoring turbines to the seabed. While these installations are limited to shallower areas, large-scale turbines can be employed.

Currently in Japan, most offshore turbines are also fixed-bottom. However, with the country’s coastal waters getting deep quite close to shore, “floating” offshore wind systems—which have fewer location constraints—are gaining attention. Because Japan holds the world’s sixth-largest EEZ (Exclusive Economic Zone), floating systems could pave the way for large-scale offshore wind deployment. Government-led efforts are underway to drive down costs and develop suitable equipment.

External image of a wind turbine Photo, courtesy of Vestas Wind Systems A/S, Photo courtesy of Hibiki Wind Energy Co., Ltd.

Hokkaido Boasts the Highest Potential Nationwide

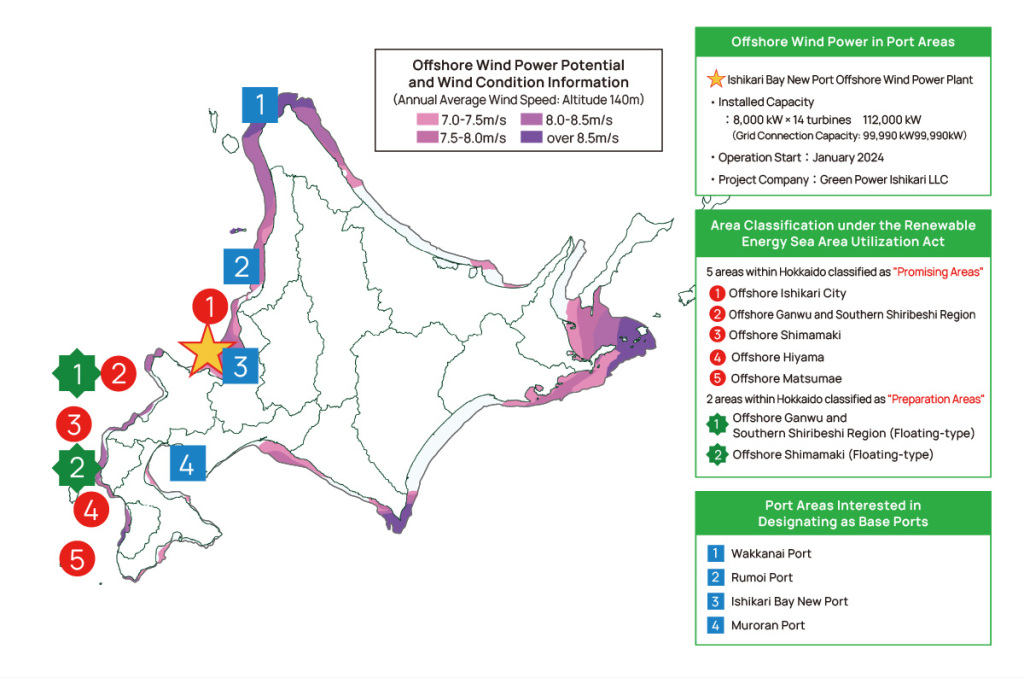

When it comes to offshore wind power, Hokkaido leads the country in potential, owing to strong maritime winds compared to other regions and favorable wind conditions offshore.

In May 2023, the Japanese government designated five offshore areas—off the coast of Ishikari City, the Iwau and Minami-Shiribeshi districts, Shimamaki, Hiyama, and Matsumae—as “promising zones” for offshore wind power. The next step is to gain official “promotion zone” status, which requires confirming favorable natural conditions (meteorological and oceanic) and ensuring no significant interference with fisheries or shipping.

Large-scale offshore wind farms are already underway. In Ishikari Bay, a commercial offshore wind power plant of unprecedented capacity for Japan began operations in January 2024. It features 14 turbines, each rated at 8,000 kW—the first installation in Japan of wind turbines at this scale—producing a total of 112,000 kW. All generated power is fed into the grid via a substation.

Source: Created based on “Hokkaido’s Renewable Energy Potential and GX Industry Possibilities” by the Hokkaido Zero Carbon Promotion Bureau, Department of Economic Affairs.

Maintenance as the Backbone of Wind Power

Japan and Europe differ substantially in terms of weather conditions for wind power. Most wind turbines in Japan are imported, but severe weather phenomena unique to Japan—such as typhoons, lightning strikes in winter, or turbulent winds—require special attention to avoid breakdowns.

Equipment maintenance is vital to ensuring stable power generation and supply. In Hokkaido, there is a company supporting wind power through maintenance.

Hokutaku (headquartered in Asahikawa, Hokkaido) recognized the importance of maintenance over 20 years ago, during the wind industry’s infancy, led by one of its founders, Mr. Satoru Yoshida. Today, it provides inspection, repair, and component supply services for roughly 80% of the approximately 2,600 wind turbines in Japan. As an independent, third-party service provider not affiliated with any specific manufacturer or project operator, it commands the largest share of the domestic maintenance market.

According to Senior Managing Director Hibiki YOSHIDA, “Our strengths come from over 20 years of on-site experience, long-accumulated expertise, creative thinking, and international networks. We own an onshore wind farm and training center for our own engineers, helping us enhance their skills and distinguish ourselves from other firms.”

Mr. Hibiki YOSHIDA, Senior Managing Director, Hokutaku Co., Ltd. Photo courtesy of Hokutaku Co., Ltd.

Building ties with turbine manufacturers and forming strong relationships throughout the supply chain is also essential for maintenance. Hokutaku partners with both domestic and international parts suppliers, enabling it to source components that are difficult to obtain in Japan or have gone out of production.

By collaborating with the world’s largest gearbox manufacturer, the company has established local inspection and repair teams, offering onboard repairs and refurbished parts. It has also teamed up with a brake manufacturer, allowing it to repair or overhaul brake systems—key components of wind turbines. Such accomplishments attest to the company’s solid reputation in the industry.

Photo courtesy of Hokutaku Co., Ltd.

Driving Industry Growth Through Workforce Development

“Wind power is thriving not only on land but also offshore. With floating offshore wind, even in Europe—where offshore wind leads the way—few cases have reached a full mainstream level yet. We in Japan see this as an opportunity to promote our own technology,” says Senior Managing Director Yoshida, expressing high hopes for offshore wind. In January 2024, Hokutaku announced a capital alliance with shipping giant Mitsui O.S.K. Lines. By leveraging Hokutaku’s maintenance know-how and the MOL Group’s operational experience in social infrastructure, the two aim to contribute to the entire offshore wind sector.

Offshore wind maintenance work calls for a different skill set than onshore operations, as personnel must reach the site by ship and work in unstable conditions. Hokutaku has therefore established a training facility in Kitakyushu City, Fukuoka Prefecture, specializing in O&M (operation and maintenance) for offshore wind. There, trainees can practice moving from a specialized vessel simulating ocean swells onto the turbine, and even helicopter hoist operations—letting them safely master offshore scenarios on land.

In Europe, a wealth of maritime industry experience has been cultivated through offshore oil and gas exploration, and many technicians have shifted to offshore wind. By contrast, Japan lacks extensive offshore industries, making talent recruitment and training a significant challenge.

Hokutaku also engages in outreach aimed at younger generations—for instance, accepting high school and technical college students for internships. “We established the training center for the benefit of the industry rather than to boost a single company’s profits,” says Yoshida. “We hope many businesses and operators working in offshore wind will use it, so we can reduce accidents and turn out skilled professionals that will support wind farm operations. That’s our way of contributing to offshore wind’s future growth.”

Photo courtesy of Hokutaku Co., Ltd.

Partnering with Local Communities to Generate Jobs

From manufacturing to assembly, and on to O&M, building a robust supply chain is essential for deploying offshore wind farms. With five promising areas identified across Hokkaido, work is underway to explore supply chain structures and opportunities for local companies to enter the market.

However, the vast majority of wind turbines are produced in Europe. “Breaking into the manufacturing phase itself may be quite challenging,” Yoshida observes. “On the other hand, it may be possible in the O&M phase to replace certain components with Japanese-made parts or to handle repairs domestically, building a Japanese-style supply chain.” By tapping into local corporate know-how, longer turbine lifespans may be supported close to home.

At the same time, long-term operation depends on O&M. In offshore wind, not just the turbines but also the BOP (Balance of Plant) require ongoing maintenance.

In Hokutaku’s case, the company either subcontracts work to local partner firms or hires them as Hokutaku employees for tasks in their respective regions—thus contributing to local employment. The same approach will likely be adopted for offshore wind development in Hokkaido’s promising zones, creating jobs across the region.

“As offshore wind projects unfold, the relationship with the community continues for 20 years through O&M, not just the construction phase,” Yoshida remarks. “Living in harmony with local communities is crucial.” Gaining the acceptance of regional stakeholders—particularly the fishing industry—will be vital. Demonstrating benefits such as new business opportunities and expanded employment helps ensure local support, which in turn propels further growth in offshore wind.

Greater Collaboration for the Continued Expansion of Offshore Wind

For many years, Hokutaku has gone beyond maintenance, providing essential underpinnings for wind power as a whole. “With the entire industry facing a shortage of skilled labor, it’s important to cooperate where we can support one another,” Yoshida says, looking ahead. “Especially for offshore wind, collaboration with regional governments is also critical.”

Japan’s offshore wind power sector still has enormous room to grow. Hokkaido, in particular—encircled by ocean and exposed to strong maritime winds—offers great promise. National targets call for up to roughly 45 GW of offshore wind by 2040, with Hokkaido alone expected to account for about 15 GW, or a full third. Hokkaido’s contribution will be central to Japan’s offshore wind ambitions. Being designated as a promising zone, together with pioneer companies that have backed wind power for over 20 years, also sets the stage for progress.

As in Hokutaku’s recent partnership with Mitsui O.S.K. Lines, new value created by applying proven know-how could be a game-changer. Achieving Green Transformation (GX) via offshore wind requires collaboration among industry, government, and local communities.