Leveraging Local Hokkaido Resources in a Dairy-Farming Town: The Hydrogen Supply Chain Efforts of “Shikaoi Hydrogen Farm”

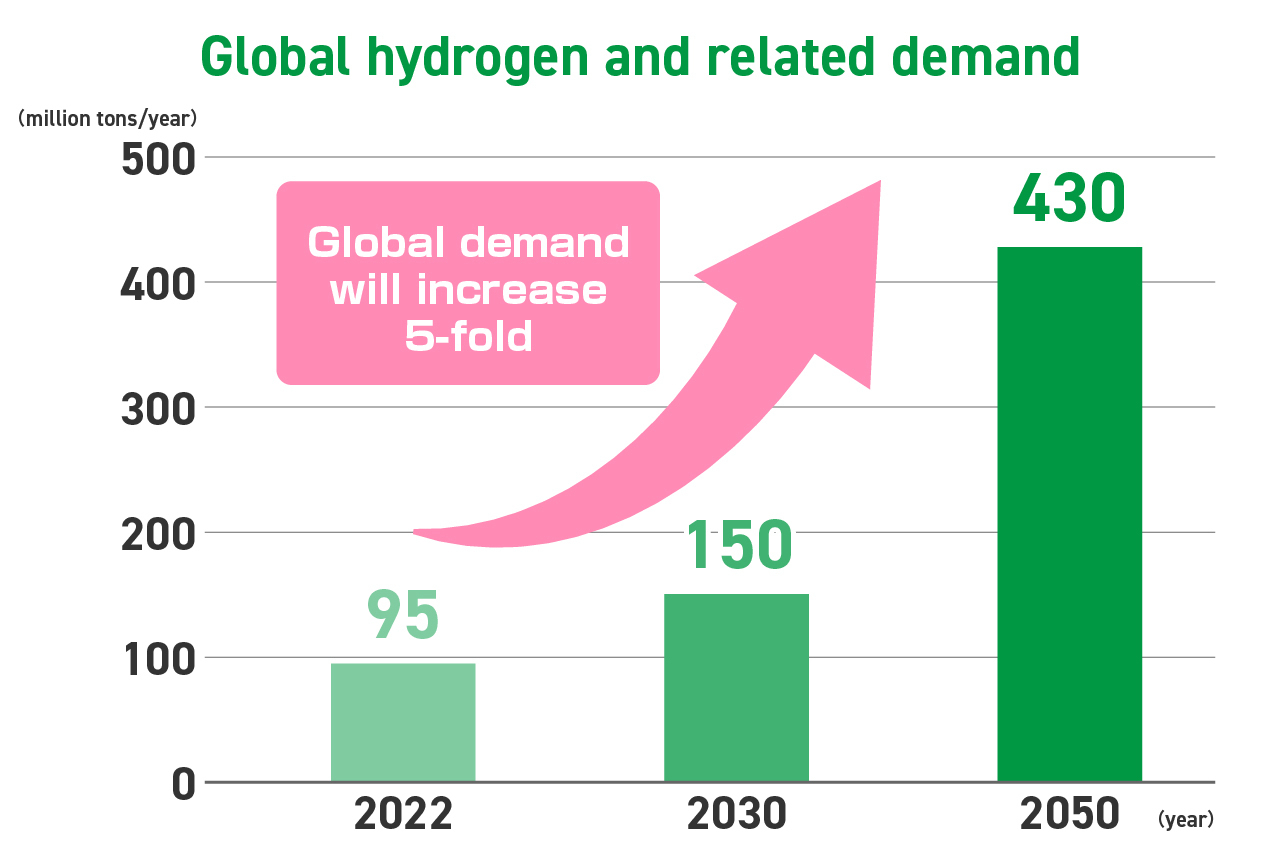

Globally Increasing Demand for Hydrogen

Over the next 28 years, global demand for hydrogen is forecast to grow fivefold

It is said that 14.5% of the world’s greenhouse gas emissions come from the livestock industry, with a large portion attributed to livestock manure. Converting what could be termed a “nuisance,” livestock manure, into biogas or hydrogen as part of climate change measures has therefore drawn considerable attention.

In Europe, particularly in advanced cases like Denmark, manure-derived biogas is used for biogas power generation as well as to supply heat to regional buildings via “heat networks.”

Worldwide demand for hydrogen is expected to surge even further across industries such as steelmaking and chemicals, mobility, and power generation on the road to carbon neutrality. By 2050, hydrogen demand may be about five times higher than in 2022.

Source: Created based on “Net-Zero Roadmap” by the IEA (September 2023)

Converting Manure in Dairy-Farming Regions to Hydrogen

Hokkaido accounts for more than half of Japan’s total raw milk production. In Tokachi, which is one of the nation’s leading dairy regions, about 240,000 dairy cows are raised. In this region, there is an initiative to produce hydrogen derived from livestock manure.

Let us take a look at “Shikaoi Hydrogen Farm,” which capitalizes on the characteristics of an area where dairy farming thrives.

Photo courtesy of Shikaoi Town

Local Challenges and Solutions

A Biogas Plant Established to Address Odor Problems

In Shikaoi Town, located in central Hokkaido, a population of 5,000 is home to about 100 dairy farms raising 21,000 dairy cows.

Because the town center lies close to the farms, the smell resulting from manure treatment has long been an issue. As dairy operations became larger, the volume of manure—and the labor required to treat it—increased significantly. Residents and tourists voiced concerns, making a solution an urgent priority.

In response, the town established an Environmental Conservation Center in 2007 and began operating a centralized biogas plant. Two plants are now active.

The biogas produced is used for power generation. It is also refined and compressed to make it usable in burners designed for methane gas. Furthermore, the residual heat is now used to raise sturgeon, and even to grow tropical mangoes in winter. These applications are expanding within the region.

Photo courtesy of Shikaoi Town

The biogas produced is used for power generation. It is also refined and compressed to make it usable in burners designed for methane gas. Furthermore, the residual heat is now used to raise sturgeon, and even to grow tropical mangoes in winter. These applications are expanding within the region.

Photo courtesy of Shikaoi Town

Photo courtesy of Shikaoi Town

More Than Half of Japan’s Biogas Plants Are in Hokkaido

In Germany, a global leader in biogas power generation, nearly 10,000 plants are in operation.

In Japan, there are around 200 plants total, and more than half—about 150—are found in Hokkaido. Odor-control measures are a driving factor, with many plants located in Tokachi.

Activities of “Shikaoi Hydrogen Farm”

Looking to make even more effective use of biogas, stakeholders chose hydrogen as their next step.

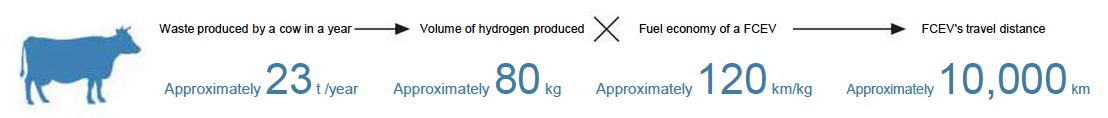

A single cow produces about 23 metric tons of manure per year. From that amount, it is possible to generate enough hydrogen to fuel a fuel cell vehicle for around 10,000 km of driving.

Source: Shikaoi Hydrogen Farm Co., Ltd.

Starting in 2015, Air Water and Kajima Corporation launched verification projects supported by the Ministry of the Environment, and in 2022 they turned those efforts into a full-fledged business. This is the first facility in Japan to produce hydrogen from manure-derived biogas on a commercial scale. Located on the grounds of the town’s Environmental Conservation Center, it also includes a hydrogen station.

Air Water originally focused on biogas-related technology development in Hokkaido. They possess high-level expertise, such as converting manure-derived biogas into liquefied biomethane (LBM), which can serve as a substitute for LNG (liquefied natural gas).

This undertaking—transforming locally sourced biomass into hydrogen—has attracted a great deal of attention, bringing visitors not only from within Japan but also from countries like Germany, Chile, and Laos, as well as media outlets from overseas.

Photo courtesy of Shikaoi Town

How Hydrogen Is Generated

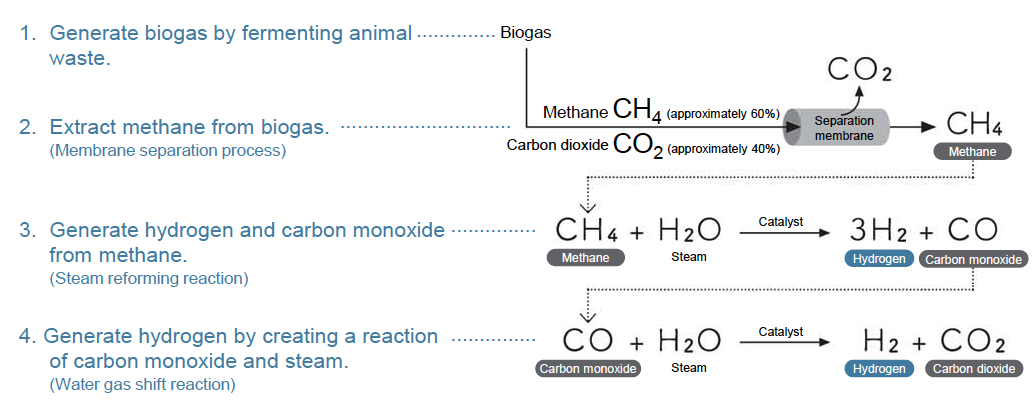

The hydrogen production process works as follows. First, carbon dioxide is separated out from biogas, extracting methane gas. Hydrogen and carbon monoxide are then generated from that methane. Next, the carbon monoxide reacts with steam to produce additional hydrogen. Finally, the hydrogen is compressed to become usable fuel.

Source: Shikaoi Hydrogen Farm Co., Ltd.

Stable Hydrogen Production and Supply

Shikaoi Hydrogen Farm can produce up to 500,000 Nm³ of hydrogen per year—the equivalent of what can be made from the manure that about 550 cows produce in one year.

It is compressed onsite at the hydrogen station and sold as fuel for fuel cell vehicles. It is also used to fuel fuel cell forklifts on the premises. In the future, they aim to store and transport it in high-pressure vessels for distribution as hydrogen gas.

Achieving a Sustainable Business Through Local Understanding and Technical Expertise

A major advantage for Shikaoi Hydrogen Farm is the local acceptance it enjoys, paired with many years of accumulated technical expertise.

First and foremost, securing livestock manure as a raw material is indispensable. Since many producers had been troubled by manure disposal for years, the town supports efforts that streamline proper treatment.

From hydrogen production through transportation, the business leverages Air Water’s extensive know-how in supplying industrial gases.

In the process of generating hydrogen, methane is first extracted from the biogas, then converted into hydrogen using hydrogen generation equipment owned by Air Water.

Shikaoi Town sees temperatures drop to around minus 20°C in winter. Shikaoi Hydrogen Farm President, Mr. Junya Suenaga, points out, “Our technology is strong enough to produce hydrogen from manure-derived biogas even in such a cold region. That is a distinct advantage.”

Mr. Junya Suenaga (left), President of Shikaoi Hydrogen Farm Co., Ltd., and Mr. Yoichi Abo (right) of the same company

For transport, Air Water’s existing distribution network across Hokkaido is utilized, and the hydrogen can be carried in high-pressure gas cylinders. In a demonstration test, fuel was delivered daily to a zoo located 30 km away that housed a stationary fuel cell.

Furthermore, the company supplies certified personnel such as high-pressure gas safety supervisors required to operate the hydrogen station.

Instead of relying on an ultra-novel technology, Shikaoi Hydrogen Farm has managed to develop a sustainable business thanks to the robust skills and human resources accumulated over many years.

The hydrogen it produces powers fuel cell vehicles owned by the town and by private businesses, which now use these vehicles for official duties and sales calls—running in and out of Shikaoi on hydrogen.

In this way, the town of 5,000 residents has built an entire supply chain—“produce hydrogen,” “transport and store it,” and “use it.”

Mr. Suenaga says, “It’s people that form a community. If you want to move a project forward, you have to gain their agreement and support, in a way that helps build the future. In driving GX (Green Transformation), I feel that working closely with local communities is more important than ever.”

Photo courtesy of Shikaoi Town

Advancing Hydrogen Utilization in Sapporo

In Sapporo, efforts are underway to develop urban planning that takes advantage of hydrogen energy.

Having declared itself a Zero Carbon City in 2020, the city has made significant strides in addressing climate change. However, after suffering a large-scale blackout during the Hokkaido Eastern Iburi earthquake in 2018, ensuring an energy supply that remains reliable even in emergencies has become a major challenge.

To build a city resilient to disasters and friendly to the environment, Sapporo has designated its central urban area as a pilot district for consuming and utilizing hydrogen. In April 2025, a hydrogen station will fully open, and a private-sector plan to install a pure-hydrogen fuel cell at a new multipurpose facility is also in the works.

In the transportation sector, the city is providing support for introducing hydrogen-powered commercial vehicles.

By incorporating hydrogen energy into urban development, the city aims to achieve decarbonization, ensure a stable energy supply, and invigorate the regional economy.

Local Production and Consumption of Energy in a Distinctly Hokkaido Fashion

Making Energy More Familiar Through Local Production and Consumption

In Shikaoi Town, livestock manure long considered a headache was converted into biogas, further upgraded into hydrogen, and turned into a key that opens new possibilities.

By flipping a challenge on its head and combining technologies, it has become a chance to expand the region’s potential.

Mr. Suenaga of Shikaoi Hydrogen Farm notes, “Hydrogen is surely a clean, decarbonized option, but to encourage wider knowledge and use, positioning it like local vegetables—as ‘produced in Shikaoi’—feels much more natural to me.”

When the manure from local cows helps power cars and heating systems, that energy can be “locally produced and consumed” just like vegetables. Then, energy is no longer a faraway concept dependent on global markets, but something more familiar, with a clearly recognizable source.

Once local residents can feel close to the energy that supports them, momentum toward GX will only accelerate further.

Harnessing the Individual Strengths of Hokkaido’s 179 Municipalities to Create Energy

Hokkaido has 179 municipalities, each with its own unique strengths.

Many areas are undertaking studies or demonstrations for hydrogen supply chains—covering everything from production to transport. In Mikasa City, a study was done on making hydrogen from coal and woody biomass. In Muroran City, a trial was carried out to deliver wind power–generated hydrogen through existing gas distribution networks.

Rich in natural resources, Hokkaido is a “treasure trove” of potential. There is a great deal of possibility in creating new forms of energy that play to each region’s individuality. At the same time, achieving this requires partnership with local industries and residents, and addressing local challenges together.

Tapping into the diverse identities and cultivated know-how of each community to generate new value could very well be the hallmark of Hokkaido’s unique approach to GX.